One of our viewers raised a very important question. Why do we bond at the Service Panel and not at the sub-panels? This is a very valid and super important question. A question that Dustin brings answers to in this article and the video below.

The Principle of Electrical Bonding

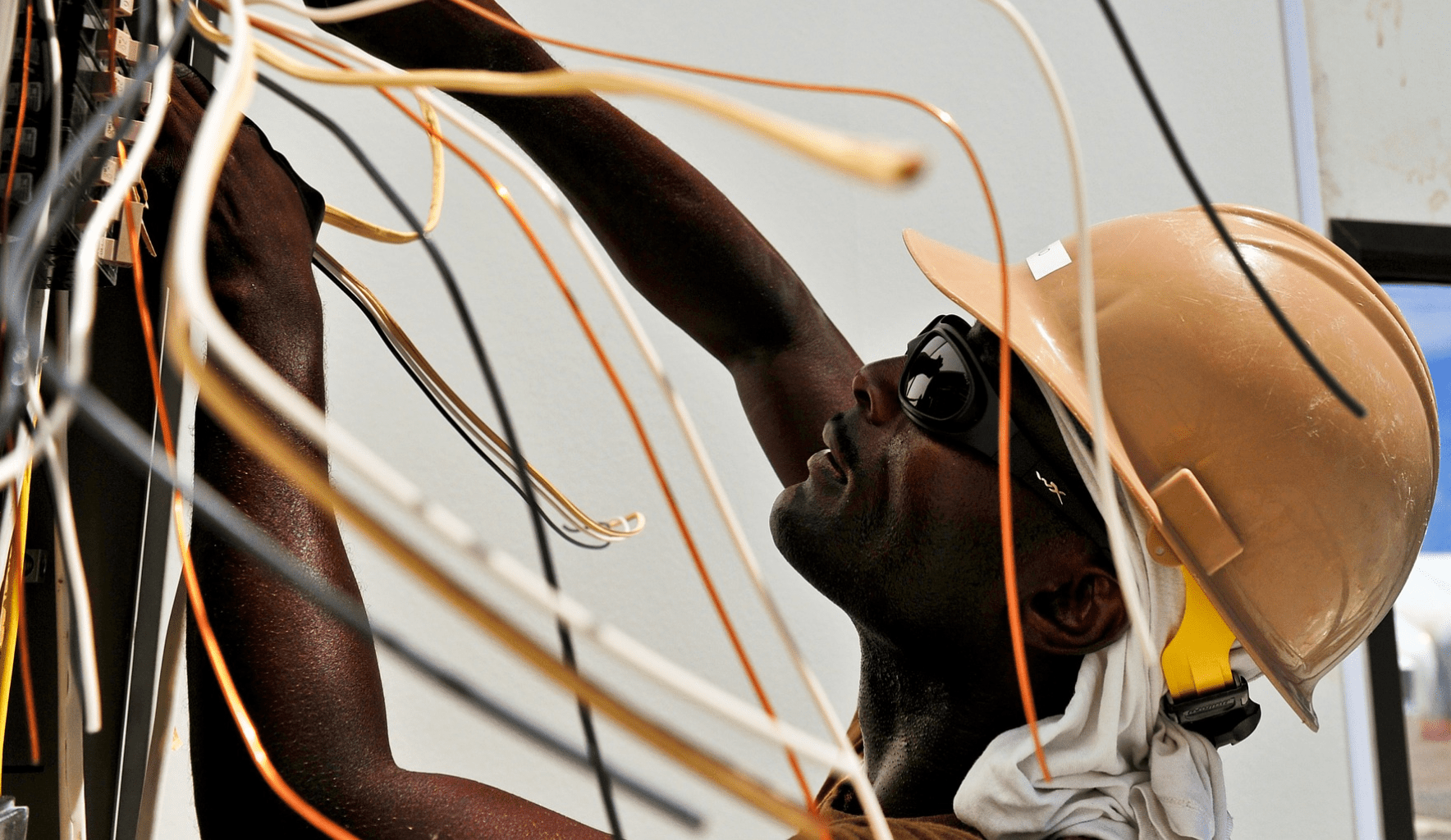

Many electricians widely practice bonding neutral and ground together at the service panel and not at the sub-panels when wiring electrical services. One might wonder why this is done. The answer to this crucial question lies in understanding the basic mechanics of electrical circuits. The service panel receives ungrounded (hot) conductors and grounded (neutral) conductors in a standard setup. Note there is no equipment grounding conductor brought into the service. Rather a ground is “derived” from the bonding point with a neutral. The main service disconnecting means represents the primary juncture where the neutral and grounding conductors interconnect or bond.

Following this, the conductors may proceed to another panel, where the neutral and ground conductors remain separated. For more information about why we bond, check out this YouTube video we made about bonding electrical services.

The Significance of Grounding Conductor

The primary function of the equipment grounding conductor is to establish a fault path from the metal enclosure, or parts, near energized conductors. Touching an energized metallic casing of a piece of equipment can result in an electric shock. So a method of ensuring a breaker trips when this happens, is crucial.

The grounded neutral conductor on the secondary side of the utility transformer allows us to carry fault current from a fault back up to the transformer. In doing this we allow a complete loop from the fault, to the transformer, and back to the fault. When we bond all of the equipment grounding conductors together with the system neutral, we allow any fault-current from a ground-fault anywhere on the system to take the path back up to the transformer, via the system neutral. This completes a circuit, allowing for an incredible amount of current to travel through the circuit. Which then forces the energized circuit conductor’s breaker to trip. Without this grounding conductor protecting metallic equipment, there is no other means available to de-energize this equipment if a person were to touch it.

Mitigating Objectionable Current

The main reason for maintaining the separation of conductors beyond the service panel is to combat the problem of Objectionable Current. This phenomenon occurs when current unexpectedly diverts into unanticipated pathways. Under normal circumstances, current travels via the hot wires and finds its way back either through the grounded or another ungrounded conductor.

However, when a wire becomes disconnected and unintentionally makes contact with other surfaces, Objectionable Current surfaces. This causes the current to stray off its intended path. The neutral conductor carries any imbalance which occurs between two or more circuits, whereas ground conductors should never carry current. By bonding at the service panel only, we restrict Objectionable Current from flowing through both the neutral and ground simultaneously. Avoiding potential electrical chaos. Separating conductors effectively controls the desired current flow, significantly reducing the likelihood of electrical complications.

Responding to Ground Faults

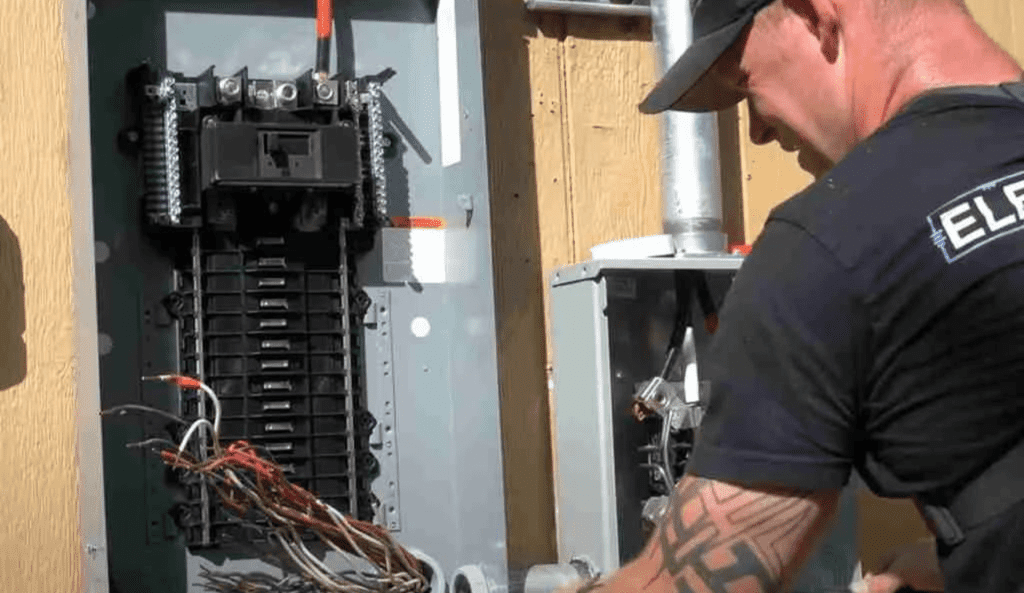

Consider a scenario where a ground fault occurs. For instance, when an ungrounded conductor comes into contact with a dryer’s casing. In such an event, the grounding conductor carries the objectionable current back to the service panel, where it bonds with the neutral to complete the circuit. The load is no longer part of the equation as the contact with the casing bypasses the load. Leading to a surge in current that trips the breaker, as intended. Without a grounding conductor and completed circuit, there would be potential for current to flow through all downstream metal from the service point, as well as all neutrals along the way, which could cause serious harm to other equipment.

Why Not Bond at Every Panel?

You might think that additional ground-to-neutral bonding at each panel location would be beneficial. However, if bonding occurred at every panel, multiple paths for the current could form. Potentially leading the current away from its source, thereby defeating the purpose of current control. Moreover, if the neutral and ground were bonded at every panel, it could potentially send electrical energy to every device connected to all circuits under certain circumstances. All neutrals and all grounds could potentially carry fault-current at the same time.

For this reason, the bonding of all grounds and neutrals is carried out at one specific point only – the service panel. This strategy helps maintain control over the current flow, preventing it from energizing other connected devices or systems, thus ensuring safer and more efficient electrical circuits.